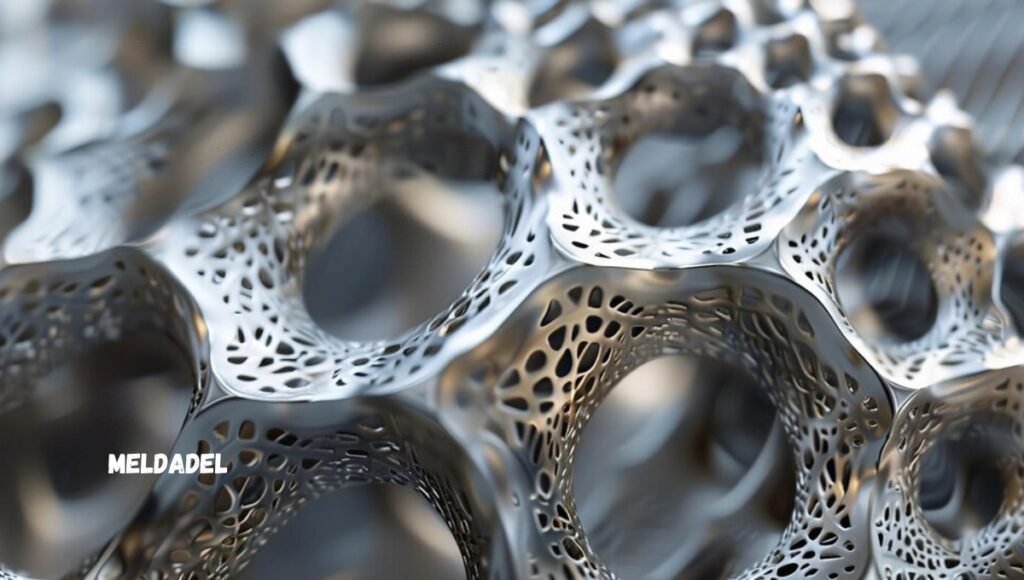

Introduction to Meldadel

In recent years, technological advancements have ushered in a new era of materials science. One of the most promising innovations in this field is Meldadel. This cutting-edge material has been gaining significant attention across various industries due to its unique properties and wide range of applications. But what exactly is Meldadel, and why is it considered the future of hybrid materials?

What is Meldadel?

Meldadel is a novel hybrid material that combines the best features of both metals and polymers. By integrating the strength and durability of metals with the flexibility and lightweight nature of polymers, Meldadel offers a versatile solution for various engineering and industrial applications. This innovative material is designed to overcome the limitations of traditional materials, providing enhanced performance, longevity, and efficiency.

The Science Behind Meldadel

The creation of Meldadel involves an intricate process of molecular engineering. Scientists have developed advanced techniques to bind metallic components with polymer matrices at the molecular level. This fusion results in a material that exhibits the superior characteristics of both metal and polymer, without the weaknesses typically associated with each. Meldadel’s structure is highly customizable, allowing it to be tailored to specific needs, making it a revolutionary material in the field of engineering.

Applications of Meldadel

The versatility of Meldadel makes it a valuable asset in numerous industries. Here are some of the most notable applications:

1. Automotive Industry

In the automotive sector, weight reduction is a critical factor in improving fuel efficiency and reducing emissions. Meldadel’s lightweight yet strong properties make it an ideal material for manufacturing car components. It can replace traditional metal parts, resulting in lighter vehicles without compromising safety or performance.

2. Aerospace Engineering

The aerospace industry demands materials that can withstand extreme conditions while remaining lightweight. Meldadel fits this criterion perfectly. Its application in aerospace engineering includes the production of aircraft components, where it helps reduce weight, improve fuel efficiency, and enhance overall performance.

3. Medical Devices

Meldadel’s biocompatibility and flexibility make it a promising material for medical devices. It is particularly useful in the creation of implants, prosthetics, and surgical instruments. The material’s ability to resist corrosion and its lightweight nature ensure that medical devices are both durable and comfortable for patients.

4. Construction Industry

In construction, Meldadel can be used to create stronger, more durable building materials. Its resistance to corrosion and environmental degradation makes it ideal for structures that need to endure harsh conditions over time. Meldadel can be utilized in everything from structural supports to external cladding, providing long-lasting and reliable construction solutions.

5. Electronics and Technology

The electronics industry is constantly seeking materials that can enhance the performance of devices while reducing their size and weight. Meldadel’s electrical conductivity, combined with its flexibility, makes it an excellent choice for producing smaller, more efficient electronic components. It can be used in everything from circuit boards to wearable technology.

6. Energy Sector

In the energy sector, Meldadel has potential applications in the development of more efficient solar panels and wind turbines. Its strength, durability, and lightweight nature allow for the creation of energy-efficient components that can withstand the elements while maximizing energy output.

Benefits of Using Meldadel

Meldadel’s unique properties offer several advantages over traditional materials:

1. Strength and Durability

Meldadel combines the strength of metals with the flexibility of polymers, resulting in a material that is both strong and durable. This makes it suitable for applications where high strength and long-term reliability are crucial.

2. Lightweight

One of the most significant benefits of Meldadel is its lightweight nature. This property is particularly important in industries like aerospace and automotive, where reducing weight can lead to better performance and fuel efficiency.

3. Customizability

Meldadel can be engineered to meet specific needs, making it a highly versatile material. Whether it’s adjusting the balance between strength and flexibility or optimizing it for specific environmental conditions, Meldadel can be tailored to suit a wide range of applications.

4. Corrosion Resistance

Unlike many metals, Meldadel is highly resistant to corrosion, making it an excellent choice for applications in harsh environments. This property extends the lifespan of products made from Meldadel, reducing the need for frequent replacements and maintenance.

5. Cost-Effective

While advanced in its design, Meldadel is also cost-effective in the long run. Its durability and reduced maintenance needs translate to lower overall costs, particularly in industries where equipment longevity is paramount.

The Future of Meldadel

The development of Meldadel represents a significant leap forward in materials science. As research continues and production processes become more refined, it is expected that Meldadel will become even more prevalent across various industries. Its potential to revolutionize everything from transportation to healthcare makes it a material of the future.

Ongoing Research and Development

Scientists and engineers are continuously exploring new ways to enhance Meldadel’s properties and discover new applications. This ongoing research is likely to lead to even more innovative uses for the material, further solidifying its place in the future of industry.

Environmental Impact

Meldadel’s potential to replace traditional materials also carries environmental benefits. Its lightweight nature can reduce the energy consumption of vehicles and aircraft, leading to lower emissions. Additionally, its durability reduces the need for frequent replacements, thereby minimizing waste.

Challenges and Considerations

Despite its many advantages, there are still challenges associated with the widespread adoption of Meldadel. These include the cost of production, the need for specialized manufacturing processes, and potential regulatory hurdles in industries like healthcare and aerospace. However, as technology advances and economies of scale come into play, these challenges are expected to diminish.

Conclusion

Meldadel stands at the forefront of material innovation, offering a unique combination of strength, flexibility, and durability that could transform numerous industries. As research and development continue to push the boundaries of what this material can do, its applications are likely to expand even further, solidifying its role as a key player in the future of materials science.